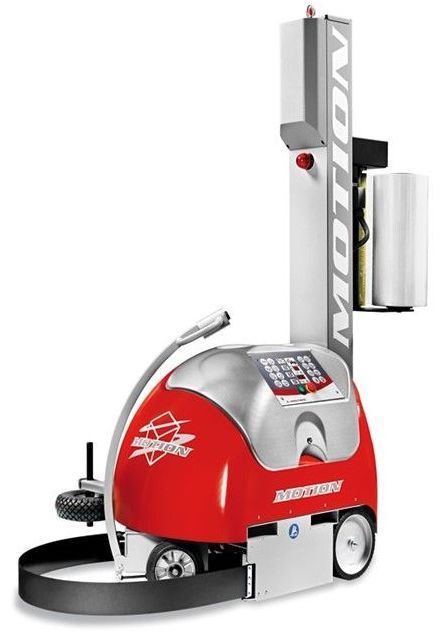

Motion

Self-driving stretch robot

Operational Features

- Mobile, battery-powered solution

- Pallet loads with high weight

- Pallet loads with virtually unlimited side lengths

- Unstable pallet loads

- Independent movement around the packaged goods

- Little space required in confined spaces / pallet locations

- Changing wraps due to different packaged goods requirements

- The gradient speed of the film carriage, which can be adjusted on the control panel, allows the film overlap to be varied

- Photocell to detect the pallet height and control the stretching process

- Stretching of a complete pallet (standard) possible in less than 1 minute

- Only 1,100 mm of space required next to the pallet to be wrapped

- Fast threading system (only with 100 MPS)

TECHNICAL SPECIFICATIONS

| Technical specifications | Motion |

|---|---|

| Max. circle speed | 93 m/min |

| Battery equipment | 2 standard gel batteries 12 V-110 Ah |

| Battery capacity | 150 / 180 pallets (depending on pallet format + number of wraps), loading cycle 8-10 hours |

| Pallet dimensions | Min. 500 x 500 mm, max. unlimited |

| Max. wrapping height | 2,200 mm (optional: 2,400 mm, 2,700 mm, 3,000 mm, 3,500 mm) |

| Min. wrapping height | 500 mm |

| Turning radius | 1,100 mm |

| Electr. connection for battery charger | 230 V, 50 Hz |

| Charger | High frequency charger in the machine |

| Machine weight | Approx. 400 kg |

| Foil type | Machine stretch film |

| Roll diameter | Max. 250 mm |

| Roll height | 500 mm |

| Roll weight | ~20 kg |

Safety features

- Front bumper (stops when hitting an obstacle)

- Emergency stop switch on the control panel

- Acoustic signal on start and stop

- Hazard light

Special equipment and accessories

- Feeler arm with double wheel (different sizes) on symmetrical or asymmetrical axle

- Larger feeler wheel (Ø 390 mm, Ø 650 mm)

- Automatic film cutting (not with 10 MB)

- 2 standard gel batteries 12 V, 110 AH (extra batteries)

- Traction battery 110 Ah, 24 V (instead of 2 standard gel batteries)

- Lithium ION battery (charging time complete approx. 1 hour)

- External battery charger (for charging an extra battery)

- Automatic refilling of the traction battery 24 V

- Front and rear wheel to avoid marks

- Automatic film cutting (not with 10 MB)

- Photocell for black detection

- Holder for film with Ø 50 mm core

- Wifi network connection (optional)

Workflow

First, the stretch robot is positioned next to the pallet. The stretch film is manually attached to the pallet and the stretching process is started. The stretch robot then moves independently around the pallet and wraps it. After the wrapping is finished, the film simply has to be cut.

control panel

| Adjustable parameters on the control panel | Motion |

|---|---|

| User-specific programmes | 99 |

| Spiral winding (up only or down only) | ✓ |

| Cross winding (up and down) | ✓ |

| Cover sheet support (rainproof) | ✓ |

| Stretching without photocell function (preset height) | ✓ |

| Ascent and descent speed of the film carriage | ✓ |

| Number of foot and head windings | ✓ |

| Speed of the robot | ✓ |

| Wrap tension separately adjustable | bottom / up / top / down |

| Pre-stretching separately adjustable (only with 100 MPS 2) | bottom / up / top / down |

| Foil overlap at the top of the pallet | ✓ |

| Identical start and stop position | ✓ |

| Weight determination of the used film (only for 100 MPS 2) | ✓ |

| Foil cut (optional; not available with 10 MB) | ✓ |

| Gradual ascent of the film carriage after each revolution | ✓ |

| Edge protector lay-on option | ✓ |

| Key lock | ✓ |

| Reinforcement windings in individual height | ✓ |

| WIFI network connection | optional |

| Foil lay-on comfort function (carriage moves to a comfortable height at the end for cutting off / relapping) | ✓ |

| Start and stop at specified heights | ✓ |

| Programme lock | ✓ |