Wingwrap

SEMI-AUTOMATIC STRETCH MACHINE

Operational Features

- Floor or wall anchoring

- Ground level loading

- Heavy pallet loads

- Unstable pallet loads

- Uneven packaged goods

- Limited space around the pallet

- Minimum space required for the machine

- Can be integrated as a fully automatic machine (see Boomerang Automatic))

- Robust steel construction of the machine

- Soft start and soft stop

- Positioned end point of the rotating arm

- Photocell for pallet height detection and stretch control

- Fast stretch film threading system (MPS only)

TECHNICAL SPECIFICATIONS

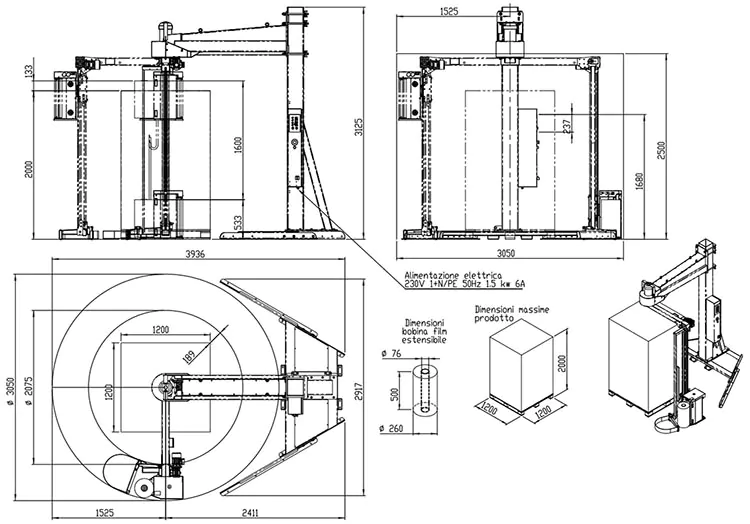

| Technical specifications | Wingwrap |

|---|---|

| Rotating arm speed | Max. 10 rpm |

| Machine performance | Approx. 25 pallettes / h |

| Rotation radius | 2,075 mm |

| Pallet dimensions | Max. 1,200 x 1,200 mm (optionally up to 1,700 x 1,700 mm) |

| Max. wrapping height | 2,000 mm (optional: 2,500 mm, 3,000 mm) |

| Min. wrapping height | 500 mm |

| Electr. connection | 230 V 1 N / PE 50 Hz 1.5 kW 6 A |

| Machine weight | 700 kg |

| Foil type | Machine stretch film |

| Roll diameter | Max. 260 mm |

| Roll height | 500 mm |

| Roll weight | ~20 kg |

Safety features

- Foil carriage with safety bar (stops the rotary arm immediately if it encounters resistance)

- Emergency stop switch on the control panel

- Acoustic signal at the start of the stretching process (optional)

Special equipment and accessories

- Available as a free-standing unit or for wall mounting

- Max. Wrapping height 2,500, 3,000 mm (2,000 mm standard)

- Automatic film cut at the end of the wrapping cycle

- Protective grid cage

- Fully automatic application, cutting and welding of the foil

- Safety fence with photocell and additional control panel on the fence (start/stop/reset)

- Turning radius (1,950 mm, 2,100 mm, 2,300 mm, 2,500 mm)

- Photocell for black detection

- Stretch cord system

- Remote control for starting the stretching process

- Freezer and cold room equipment

- Wifi network connection

- Custom-made solutions on request

Workflow

The pallet is moved into the working area of the machine. The stretch film is attached to the pallet manually (standard) or automatically (optional) and the stretching process is started. The rotating arm spins around the pallet. After the wrapping is finished, the film simply has to be cut (not applicable with optional equipment "Automatic film cut at the end of the wrapping cycle" or "Fully automatic application, cutting and welding of the foil").

control panel

| Adjustable parameters on the operator panel | Wingwrap |

|---|---|

| Spiral winding (up only or down only) | ✓ |

| Cross winding (up and down) | ✓ |

| Cross winding with cover sheet (rainproof) | ✓ |

| Cross winding without photocell function (stretching to specified height) | ✓ |

| Cross winding with reinforcement areas (manual function) | ✓ |

| Ascent and descent speed of the foil carriage (separately adjustable) | ✓ |

| Number of foot and head windings | ✓ |

| Rotating arm speed | ✓ |

| Film tension | ✓ |

| Key lock (optional) | ✓ |

| Reset function | ✓ |

| Foil overlap at the top of the pallet | ✓ |

| Number of reinforcement windings | ✓ |