Smartwrap

FULLY AUTOMATIC STRETCH MACHINE

TECHNICAL SPECIFICATIONS

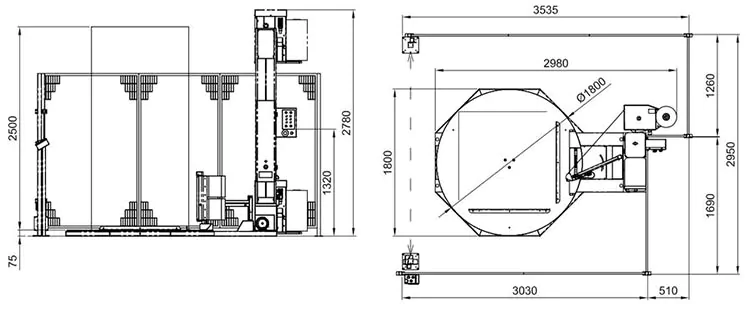

| Technical specifications | SmartWrap |

|---|---|

| Turntable diameter | 1,650 mm (optional: 1,800 mm, 2,200 mm) |

| Max. pallet dimensions | Up to 1,000 x 1,200 mm |

| Max. turntable speed | 3 – 12 revolutions / min |

| Load capacity | 2,000 kg |

| Electr. connection | 230 V, 50 Hz |

| Compressed air | 6 bar (100 Nl/min) |

| Machine weight | Approx. 600 kg |

| Machine performance | Approx. 20 pallettes / h |

| Max. wrapping height | 2,400 mm (optional: 2,200 mm, 2,700 mm, 3,200 mm, 3,500 mm, 3,900 mm) |

| Foil type | Machine stretch film |

| Roll diameter | Max. 250 mm |

| Roll height | 500 mm |

| Roll weight | ~20 kg |

Workflow

With the SmartWrap stretching machine, the pallet simply needs to be positioned on the machine's turntable with a forklift and the stretching process can be started via the remote control. After the wrapping is finished, the film is automatically cut off so that the pallet can be removed directly with the forklift. No manual action is required on the machine.

Safety features

- Emergency stop switch on the control panel

- Acoustic signal at start and stop

- Foil carriage with safety mechanism (stops when encountering resistance during downward movement)

Special equipment and accessories

- Safety fence with photocell and additional control (start / stop / reset / emergency stop)

- Stainless steel version

- For operation in hygienic areas or corrosive environments

- Galvanised version with special paint

- For operation in corrosive environments or where the metal parts are subject to heavy loads

- Welding unit (welds the end of the film to the pallet)

- Pressure pad (round + rectangular)

- Ramp for forklift

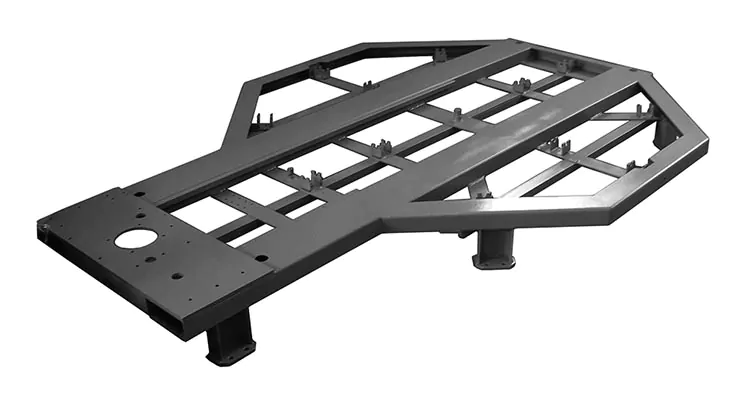

- Countersinking frame (turntable at ground level with floor)

- Elevation frame with support feet (12 cm)

- Mast offset 500 mm for protruding packaged goods

- Remote control for starting the stretching process

- Freezer and cold storage room equipment

- Integrated scales (with printer output)

- Stretch cord system

- Bubble wrap feeding system

- Strip stretch system (can be switched on as required) for air-permeable packaging - Climate-controlled packaging

- Photocell for black detection

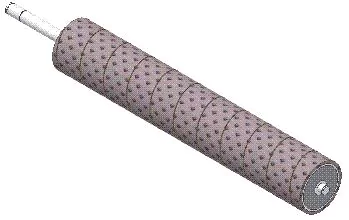

- Guide roller for net foil

- Wifi network connection

- Custom-made designs on request

control panel

| Adjustable parameters on the operator panel | SmartWrap |

|---|---|

| Spiral winding (up only or down only) | ✓ |

| Cross winding (up and down) | ✓ |

| Cross winding with cover sheet (rainproof) | ✓ |

| Cross winding without photocell function (stretching to specified height) | ✓ |

| Cross winding with reinforcement areas (automatic) | ✓ |

| Cross wrap with start at fixed height | ✓ |

| User-specific programmes | 99 |

| Ascent and descent speed of the foil carriage (separately adjustable) | ✓ |

| Number of foot and head windings | ✓ |

| Speed of the turntable | ✓ |

| Foil cut | ✓ |

| Key lock | ✓ |

| Reset function | ✓ |

| Foil overlap at the top of the pallet | ✓ |

| Pre-stretching separately adjustable up/down (only with 100 MPS 2) | ✓ |

| Application voltage separately adjustable up/down | ✓ |

| Start from a fixed height | ✓ |

| Number of reinforcement windings | ✓ |